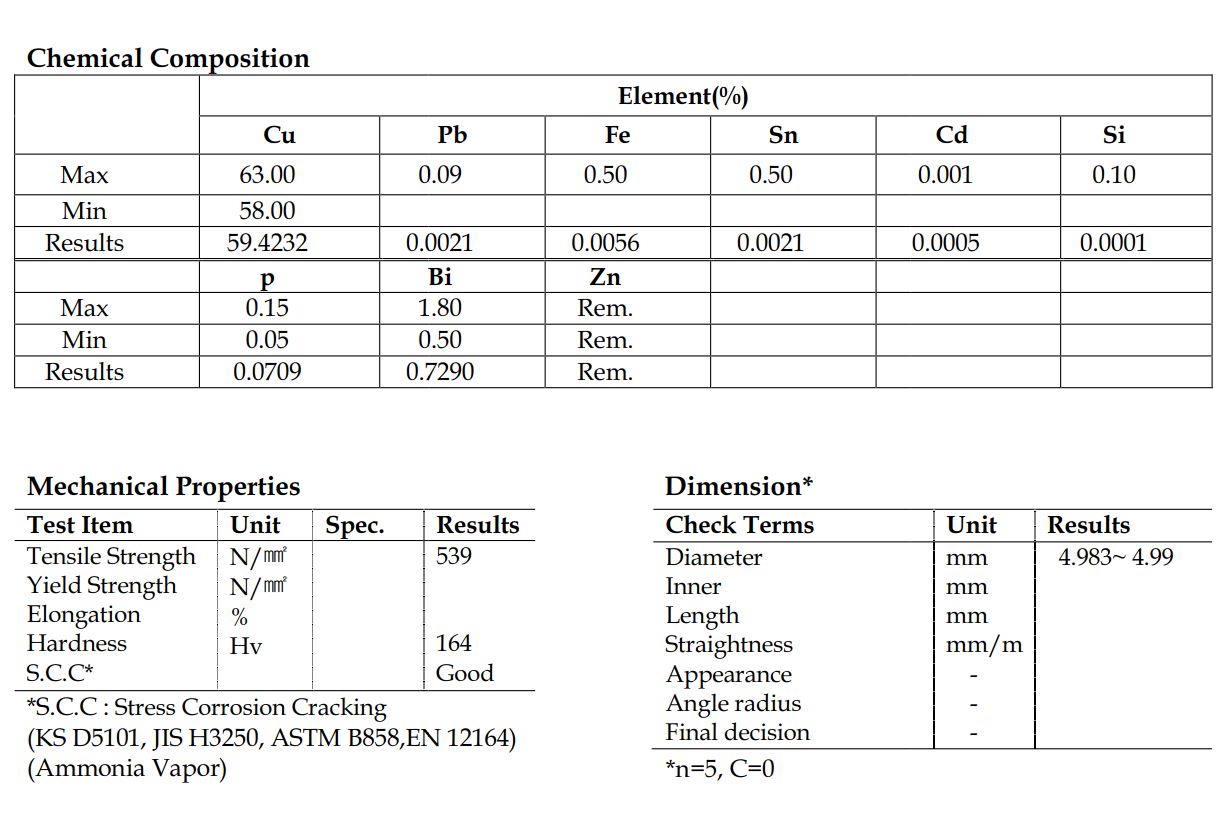

Chemical composition of the lead-free brass

4.8 (748) · $ 7.00 · In stock

Download Table | Chemical composition of the lead-free brass from publication: Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting | Results of materials testing for lead-free brass show that the effect of thermal softening decreases significantly when the strain rate is high. This behavior is referred to as thermal softening damping. In this article, a flow stress model with thermal softening damping | Damping, Thermal and Finite Element Modeling | ResearchGate, the professional network for scientists.

Modified Johnson-Cook Flow Stress Model With Therm, PDF, Deformation (Engineering)

Lead Free Brass Alloys - Benefits, Uses and Composition

Chemical composition of the lead-free brass

Bending moment of the deck resulting from Case (1) and Case (2) under

PDF) Investigation of the effect of different cutting parameters on chip formation of low-lead brass with experiments and simulations

Modified Johnson-Cook Flow Stress Model With Therm, PDF, Deformation (Engineering)

Energy vs time history of the finite element model for E s 1⁄4 5.0 GPa.

Table 1 from Effect of Replacement of Lead by Tin on The

C4926 Lead-free Brass Rod - Products

Phosphor Bronze wires - what makes them special

:max_bytes(150000):strip_icc()/metal-alloys-2340254_final-ca186a30b3454d7d936ad12114d6cdd9.png)