Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

4.5 (229) · $ 8.00 · In stock

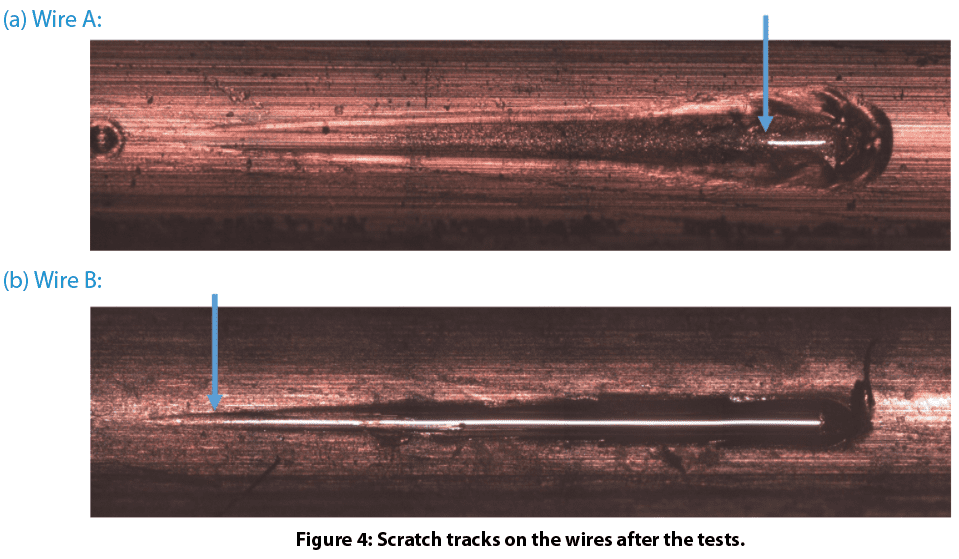

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

Fine-tuning effect of Direct Laser Interference Patterning on the surface states and the corrosion behavior of a biomedical additively manufactured beta Ti alloy - ScienceDirect

Material Hardness - from Types of Hardness to Testing & Units

Which chemical is applied for copper coins with a needle pushed test? - Quora

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

Microstructure and tribological behaviour of CoCrCuFeTi high entropy alloy reinforced SS304 through friction stir processing

ProtectaClear 4 Oz. Clear, Protective Coating for High-Touch Metal

Pet Scratch Deterrent Tape - Clear, 3-in x 90-ft, Non-Toxic, Double-Sided Adhesive for Furniture Protection

ELK Pet Scratch Deterrent Tape - Clear, 3-in x 90-ft, Non-Toxic, Double-Sided Adhesive for Furniture Protection

BUILDPRO MAX Slotted 4' x 3' Welding Table w/FREE Fixturing Kit

Die wear of 3D-printed tools when stamping steel sheet

The Material of Wire Wheel Cup Brush: Made of carbon steel material. Designed with reasonable crimped wire curvature and increased bristle thickness

6 Pcs Wire Wheel Cup Brush Set,1/4In Round Shank Wire Brush for Drill Attachment, for Cleaning Rust, Stripping and Abrasive