The FEM model for SSFSW process during the plunge phase: mesh of

4.7 (302) · $ 17.50 · In stock

Estimated void formation during FSWof dissimilar Al alloys, a Al 5083-O

Antonino Squillace's research works

Fabio SCHERILLO, Researcher, PhD

Metals, Free Full-Text

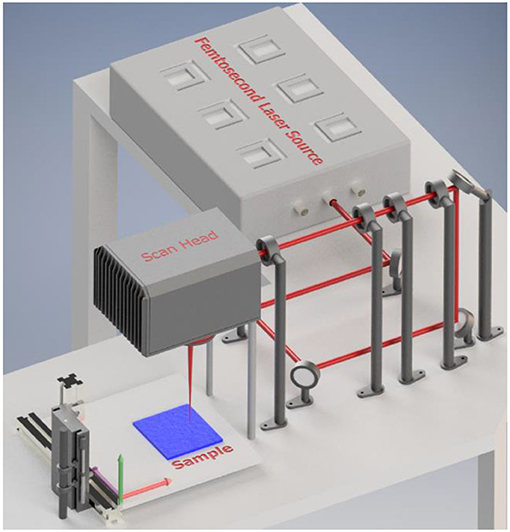

Frontiers Expedited Transition in the Wettability Response of Metal Meshes Structured by Femtosecond Laser Pulses for Oil-Water Separation

Fracture surfaces of welds made under different processing

PDF) Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061

The detailed dimensions of (a) conventional and (b) stationary

PDF) Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061

Skewness of the roughness profiles

Surface and mechanical characterization of stationary shoulder

Small strain finite element modelling of friction stir spot welding of Al and Mg alloys - ScienceDirect

Fracture surfaces of welds made under different processing